As winter approaches, many compressed air systems face a common threat: freezing temperatures. While compressors can operate at temperatures above 40 °F, unprotected equipment can freeze up at lower temperatures, leading to performance issues. This article will explore why compressors freeze and share some steps you can take to protect your system.

Do Air Compressors Freeze?

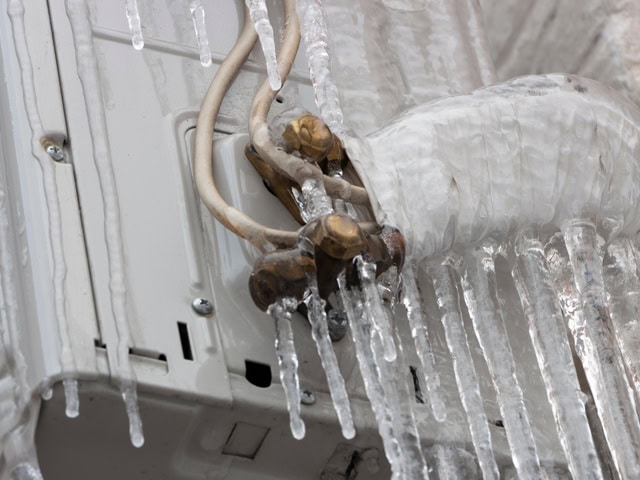

Yes, air compressors and compressor lines can both freeze at low enough temperatures. These systems generate condensate, or water vapor, which can accumulate in the pipes and on various components. When temperatures drop below 32 °F, that moisture can solidify, clogging parts like control lines, drain valves, and heat exchangers. These components can crack or sustain permanent damage, impairing the compressor’s functionality.

How to Keep My Air Compressor From Freezing

Below are some effective strategies to keep your air compressor system from freezing:

1. Weatherproof the Area

One way to keep ambient temperatures around your industrial air compressor system from dropping too low is to weatherproof the surrounding space. Maintaining a temperature of around 45 °F will be enough to prevent freezing issues in most cases. Adding heaters and improving ventilation can help keep the cold at bay in colder winter months.

2. Cold-Proof the Air Compressor System

For added protection from freezing temperatures, consider these upgrades:

Trace Heating for Pipes. Installing trace heating around pipes prevents ice obstructions and keeps dryers working efficiently.

Sump Heater. An internal sump heater can raise temperatures to the desired level for reliable system performance.

Low Ambient Temperature Switch. Using a low-temperature switch (if available for your air compressor model) can prevent permanent damage by shutting the system down in extreme cold.

Insulation. Wrapping exposed pipes and system components in insulation greatly reduces the risk of freezing.

3. Run a Proper Maintenance Schedule

Keeping up with compressor maintenance is key, especially in winter. These steps can help you avoid unexpected freeze-ups:

Check for Moisture and Ice. Inspect your air compressor and its components daily for moisture and ice buildup. Pipes and components that are far from the motor are more likely to ice over.

Check Oil Levels. Colder weather demands more of your compressor, so check oil levels frequently and switch to a winter-grade oil if needed (refer to your system manual).

Replace Filters. Filters can ice over quickly in cold temperatures; check and change them as needed to maintain adequate airflow.

4. Protect Outdoor Piping

Insulation and trace heating are vital if your compressor uses outdoor piping. Wrap outdoor pipes with insulation to trap heat and use heat tracing to combat condensation. You can also install drip legs with drain valves to minimize moisture formation.

5. Store Indoors When Possible

Indoor storage in a climate-controlled area is ideal. However, if this isn’t feasible, consider modifications like sump heaters, panel heaters, and trace heating. You’ll also need to protect control piping and drain valves exposed to cold conditions, as these small investments can save you time and money later on.

6. Check Tanks for Condensation

During winter, moisture can accumulate in air receiver tanks, which then freezes. Inspect tanks weekly for any sign of condensation buildup. A sudden increase in humidity may signal other issues in your system that need attention to avoid more severe problems.

English

English 简体中文

简体中文 French

French English

English Portuguese

Portuguese Russian

Russian Spanish

Spanish